(→Links: Added link to inverter here as well) |

m (→Links: updated links to descriptions) |

||

| Line 75: | Line 75: | ||

== Links == |

== Links == |

||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

* [https://www.kronosrobotics.com/hy02d223b-vfd-type-1/ Huanyang VFD Type 1 Inverter] Notes. Controls the Spindle. It Can be controlled by Mach3 SOftware |

* [https://www.kronosrobotics.com/hy02d223b-vfd-type-1/ Huanyang VFD Type 1 Inverter] Notes. Controls the Spindle. It Can be controlled by Mach3 SOftware |

||

| + | * -------- |

||

| ⚫ | |||

| ⚫ | |||

| ⚫ | |||

| − | * - |

||

* http://www.sawmillcreek.org/showthread.php?125009-Camtech-LaserMaster-Users |

* http://www.sawmillcreek.org/showthread.php?125009-Camtech-LaserMaster-Users |

||

* http://www.dataworks.gr/old/uk/products/specif.htm |

* http://www.dataworks.gr/old/uk/products/specif.htm |

||

Revision as of 06:21, 7 August 2024

These are our collection of notes on the Laser CNC Master Restoration Project.

Specs

- Make: Cam Tech

- Model: LaserMaster CM155

- Year:

- Working Area: X?, Y?, Z~6"

Process Overview

- Design your project in Easel (or still untested, Carbide Create)

- Export gcode file as .nc

- Setup Table

- Waste Board

- Material onto Waste Board

- Install Appropriate Mill end (bit)

- Launch UGS Software

- Reset Zero as safety

- Load .nc file

- Confirm dims with visualizer

- Move router into position

- Reset Zero For reals this time

- Create Drill locating hole

- Return to Ideal Zero

- Run project

- Try it in the air first (go up a set amount and then reset zero)

- Try it with cheap material second

- google appropriate speeds & feeds

- Try it with your final material

- Stay in shop & keep an eye on the CNC table

- take this time to help clean & organize the shop :D

- Warp up

- Clean up CNC area

- Remove project

- vacuum area

- Reset CNC for next user

Design your Project

(stem)

Setup Table

Overview: The PC controls the position of the router. The inverter on the right controls the spindle rotation.

- Turn on the PC.

- It runs on Linux Mint, but feels similar to Windows.

- Plug in the Spindle Controller

- Turn on Spindle with light switch below it

- Press "run" to start

- Adjust pot to adjust rotation

- Press "Stop" to stop rotation

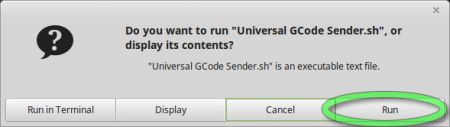

Launch UGS Software

This is the software that takes your gcode file and feeds it to the router line by line in a way that it will understand it.

Launch UGS by double clicking this icon:

New to Linux? Run the software with this option:

(stem)

(stem)

More to come on this & all sections.

Run project

(stem)

Wrap Up

(stem)

Links

- How to use Easel (free CNC software)

- First Real Project with my New Carve by CNC4NEWBIE

- CNC 3018 PRO MAX - EASEL INVENTABLES / UGS

- Huanyang VFD Type 1 Inverter Notes. Controls the Spindle. It Can be controlled by Mach3 SOftware

- --------

- http://www.sawmillcreek.org/showthread.php?125009-Camtech-LaserMaster-Users

- http://www.dataworks.gr/old/uk/products/specif.htm

- http://www.cnczone.com/forums/commercial-cnc-wood-routers/172133-cnc.html

- http://www.laserform.ca/pdf/CAMTECH_brochure_email.pdf

- LaserCut 5.x Archive

- http://www.co2-lasers.com/blog/wp-content/uploads/2012/10/MPC6535-Software.rar

- Our Copy: MPC6535-Software.rar

- Note that if you extract this under Linux you will get many duplicate file names. Presumably, these are the 32, and 64 bit system files.

- Hardware Manual: MPC6535-Hardware_Manual.pdf

- Laser Manual: Operators_Manual_48_Series-1.pdf

- Software Manual: LaserCut5.3-Software_Manual-V1.6.pdf

-- Main.ClifCox - 11 May 2016

Status

2024-08-05: It works!

NOTE: There are NO stop switches installed, so it will gladly tear through the bed, or really try hard to run itself off the rails if you let it. And if you are pinned between it and an edge, expect an emergency room visit at the least.

The X,Y& Z axis are moving. The Spindle control is working UGS works well with the system.

- tickle_pulse.zip: Arduino code for laser PWM with tickle pulse.